Clean Room Panels & Doors: Features, Applications & ISO Guidelines Explained

clean room panels India, clean room doors, modular clean room panels, PUF panels for clean rooms, clean room construction, ISO 14644 clean room guidelines, clean room panels price, clean room wall panels, clean room ceiling panels, pharma clean room panels, cold room & clean room solutions Astar Insulation.

Clean rooms are essential for industries that require a contamination-free environment. Whether it’s pharmaceuticals, hospitals, electronics, food processing, or biotechnology, the quality of clean room panels and clean room doors directly affects safety, hygiene, and product quality.

At Astar Insulation & Refrigeration, we provide high-performance clean room panels and doors designed to meet ISO 14644 standards, ensuring maximum cleanliness and controlled airflow.

What Are Clean Room Panels?

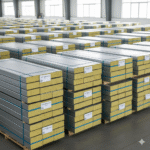

Clean room panels are insulated modular panels used to create walls and ceilings of contamination-controlled rooms. These panels prevent dust, pollutants, and microbes from entering the workspace.

Key Features of Clean Room Panels

- PUF / PIR Insulation Core

Provides excellent thermal efficiency and stability. - Smooth, Non-Porous Surface

Prevents particle accumulation and supports easy cleaning. - Leak-Proof Tongue & Groove Joint System

Ensures airtight construction to maintain pressure levels. - High Chemical & Corrosion Resistance

Suitable for pharma, chemical, and medical environments. - Anti-Bacterial Coating

Helps maintain hygiene and reduces contamination risks. - Custom Sizes & Thickness Options (40mm to 150mm)

Designed as per temperature and ISO class requirements.

Types of Clean Room Panels

1. Clean Room Wall Panels

Used to create vertical partitions in sterile environments.

2. Clean Room Ceiling Panels

Strong load-bearing panels designed to support HVAC ducts, lights, and HEPA filters.

3. Clean Room Corner Panels & Accessories

Rounded covings and aluminum profiles ensure full hygiene without dust accumulation.

Clean Room Doors: Types & Features

Clean room doors maintain pressure levels and prevent cross-contamination. Astar Insulation provides:

Types of Clean Room Doors

- Hinged Clean Room Doors

- Flush-Type Clean Room Doors

- Automatic Sliding Doors

- Air-Tight Hermetic Doors

- Emergency Exit Doors

Key Features

- Fully flush, smooth surface

- Easy-to-clean antimicrobial finish

- Air-tight sealing

- SS hardware and panic bars for safety

- Fire-rated door options

- Compatible with clean room wall systems

Applications of Clean Room Panels & Doors

1. Pharmaceutical Manufacturing

Maintains microbial control, ensuring sterile production.

2. Food & Beverage Processing

Prevents contamination during packaging and processing.

3. Hospitals & Diagnostic Labs

Used in OT rooms, ICU, diagnostic labs, and isolation rooms.

4. Electronics & Semiconductor Industries

Prevents dust to protect delicate microchips and sensors.

5. Biotechnology & Research Facilities

Creates controlled environments for experiments and culture labs.

6. Cosmetic & Chemical Industries

Ensures product purity and safe handling of sensitive materials.

ISO Guidelines for Clean Room Construction (ISO 14644)

To maintain global clean room standards, ISO 14644 offers clear guidelines.

ISO Clean Room Classification

Clean rooms are categorized from ISO Class 1 (highest purity) to ISO Class 9 (general clean).

ISO Requirements Include:

- Air quality & particle count limits

- Airflow design (laminar / turbulent)

- Number of air changes per hour

- Pressure control between rooms

- Temperature & humidity regulations

- Construction materials with smooth, cleanable surfaces

- Validation & regular monitoring

Astar Insulation clean room panels and doors fully comply with ISO 14644 requirements for pharma, food, healthcare, and industrial applications.

Why Choose Astar Insulation for Clean Room Panels & Doors?

Astar Insulation is one of India’s trusted names for PUF panels, clean room construction, cold storage, and insulated doors.

What Makes Us Different?

✔ ISO & GMP compliant constructions

✔ Factory-manufactured, precise modular panels

✔ Complete solution: panels, doors, covings, and ceiling systems

✔ Custom designs as per industry standards

✔ High-quality PUF/PIR insulation core

✔ On-time delivery & professional installation

Whether you need a clean room for pharmaceuticals, hospitals, electronics, labs, or food processing, Astar Insulation delivers high-performance and long-lasting solutions.

Conclusion

Choosing the right clean room panels and doors is the foundation of a safe, contamination-free environment. With strict ISO guidelines in place, your clean room must meet global standards for air quality and hygiene.

With Astar Insulation, you get reliable, cost-effective, and ISO-approved solutions for every clean room requirement.

best clean room panels in India

cost of clean room panels and doors

clean room panels for medical and pharma industry

ISO guidelines for clean room construction

types of clean room panels and their uses

benefits of using insulated clean room panels

clean room doors with airtight sealing

how to choose clean room panels and doors

clean room setup materials and specifications

clean room wall and ceiling panel installation

Leave A Comment: