Building a future-ready manufacturing facility in the Semiconductor, Solar, and EV sectors requires more than just high-tech machinery—it requires a flawless, controlled environment. At Astar Insulation Pvt Ltd, we provide the critical infrastructure that protects your high-precision production from the invisible threats of dust, moisture, and temperature fluctuations.

As India accelerates toward self-reliance with the India Semiconductor Mission and the rise of Gigafactories, the demand for ISO-compliant controlled environments has never been higher.

Why Clean Room Integrity is the Foundation of Tech

In high-stakes manufacturing, the “room” is as important as the “tool.” Here is how Astar’s solutions solve industry-specific challenges:

1. Semiconductors: Achieving Zero-Particulate Zones

Chip fabrication requires ISO Class 1 to Class 5 standards. Even a microscopic dust particle can bridge a circuit on a silicon wafer, leading to total yield loss.

- Our Solution: Our seamless, fiber-free PUF Clean Room Panels eliminate particulate shedding and facilitate laminar airflow, essential for maintaining the ultra-clean air quality required by leaders like Micron and Tata Electronics.

2. Solar PV Cells: Precision Climate Control

High-efficiency solar cell production is highly sensitive to humidity and chemical contamination during etching.

- Our Solution: Astar panels provide superior thermal resistance, ensuring that the strict temperature and humidity parameters required for high-yield PV cell production remain constant, 24/7.

3. EV Battery Manufacturing: The “Dry Room” Standard

Lithium-ion battery assembly is unique—it requires “Dry Room” conditions with ultra-low dew points (often below -40°C). Any moisture ingress can lead to hazardous chemical reactions or degraded battery life.

- Our Solution: Our specialized Insulated Doors and interlocking panel systems create an airtight envelope. This high-thermal-resistance barrier prevents moisture migration through walls, significantly reducing the energy load on desiccant dehumidification systems.

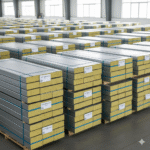

Astar’s Infrastructure Solutions

We don’t just supply materials; we build the backbone of your facility:

- Modular Clean Room Panels: Precision-fit, interlocking designs for rapid deployment and airtight seals.

- High-Performance Doors: Specifically engineered to maintain critical pressure differentials between zones.

- Thermal Efficiency: Advanced insulation that translates into massive energy savings for climate-controlled plants.

- Regulatory Compliance: Designed to help you meet and exceed rigorous ISO 14644 standards.

Powering India’s Visionaries

We are proud to support the trailblazers transforming India’s industrial landscape:

- Semiconductor: Tata Electronics, CG Power, Kaynes Technology.

- Solar: Adani Solar, Waaree Energies, Vikram Solar.

- EV: Tata Motors, Mahindra, Ola Electric, Ather Energy.

Let’s build the infrastructure that powers tomorrow. 🇮🇳

Ready to secure your production yield with world-class clean room solutions? [Contact Astar Insulation Today] for a technical consultation on your next project.

#AstarInsulation #CleanRoom #SemiconductorIndia #SolarEnergy #EVManufacturing #MakeInIndia #InsulationSolutions #TechInfrastructure #IndustrialExcellence

SEO Metadata for Your Team

- Clean Room Solutions for Semiconductor and EV

- PUF Clean Room Panels, ISO 14644 standards, EV Battery Dry Room, Solar PV manufacturing infrastructure, India Semiconductor Mission.

- Discover how Astar Insulation provides advanced PUF Clean Room Panels and Insulated Doors for India’s Semiconductor, Solar, and EV sectors to ensure ISO-compliant, moisture-controlled, and dust-free manufacturing.

Leave A Comment: