In the world of controlled environments, there is no room for error. At Astar Insulation, we take pride in our ability to execute complex industrial projects with surgical precision. Today, we are excited to share a behind-the-scenes look at our ongoing Clean Room project, where quality execution meets engineering excellence.

Establishing a high-performance cleanroom requires more than just high-quality materials; it requires a deep understanding of airflow, hygiene standards, and structural integrity.

🚧 Project Milestones: What’s Happening On-Site?

Our dedicated team is currently hitting key milestones to ensure this facility meets international cleanroom standards. Here is a breakdown of the current progress:

1. Structural Framework Installation

The backbone of any cleanroom is its structure. We have successfully initiated the structural framework, ensuring a stable and level foundation for the specialized paneling to follow.

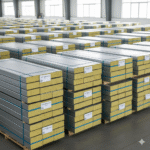

2. PUF Panel Fixing & Sealing Works

As experts in insulation, we know that PUF (Polyurethane Foam) Panels are the gold standard for cleanroom environments. Our team is currently fixing and sealing these panels to ensure:

- Thermal Efficiency: Maintaining consistent temperatures.

- Airtight Sealing: Preventing any external contamination.

- Hygienic Surfaces: Smooth, easy-to-clean finishes essential for sensitive industries.

3. HVAC Ducting Coordination

Air quality and pressure are the lifeblood of a cleanroom. We are working in close coordination with HVAC specialists to integrate ducting that ensures optimal airflow control and HEPA filtration paths, essential for maintaining the required ISO class.

4. Electrical & Utility Provisions

A cleanroom must be functional as well as sterile. We are currently integrating electrical and utility lines within the paneling system to maintain a flush, seamless finish that prevents dust accumulation.

Why Quality Execution Matters

A “Clean Room” is only as good as its weakest seal. At Astar Insulation, we focus on four pillars of execution:

- Precision: Aligning every panel to the millimeter.

- Hygiene: Using materials that resist microbial growth.

- Airflow Control: Designing for laminar or turbulent flow requirements.

- Compliance: Adhering strictly to industry norms and project specifications.

“Our commitment is to deliver a high-performance environment that doesn’t just meet the client’s specs, but exceeds industry expectations for durability and safety.”

What’s Next?

We are moving steadily toward the final stages of this project. Stay tuned for our next update, where we will showcase the final finishes and the commissioning phase.

Are you planning a controlled environment or industrial facility? Trust the experts in insulation and cleanroom construction.

Contact Astar Insulation Today to discuss your next high-performance project.

Leave A Comment: