In the rapidly evolving world of construction, efficiency is no longer just a “plus”—it is a necessity. Whether you are building a cold storage facility, a commercial warehouse, or a prefabricated home, the materials you choose dictate your long-term costs and structural integrity.

At Astar Insulation, we believe in providing solutions that balance durability with thermal excellence. That is why Sandwich PUF (Polyurethane Foam) Panels have become the gold standard for modern building envelopes.

What is a Sandwich PUF Panel?

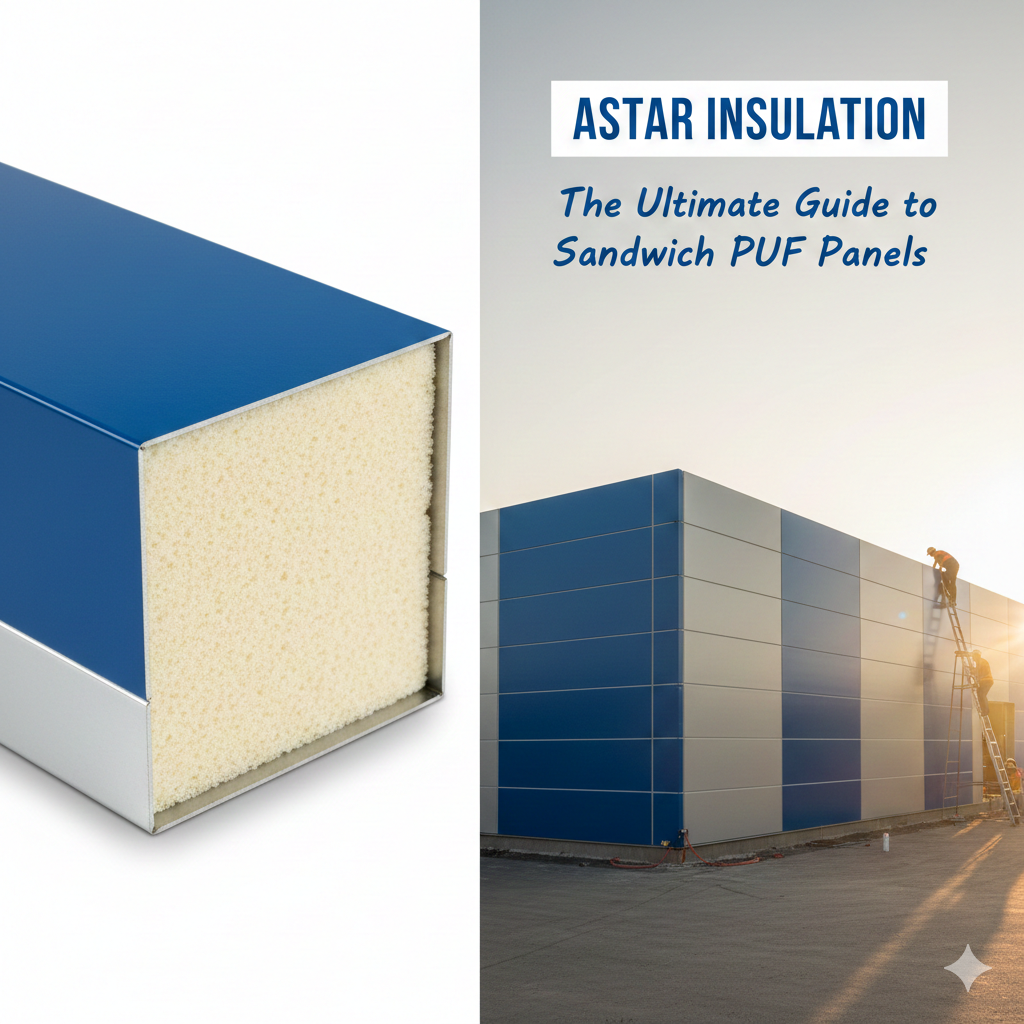

A Sandwich PUF Panel is a structural material composed of a rigid core of polyurethane foam sandwiched between two layers of galvanized or pre-painted metal sheets (usually steel or aluminum).

This “sandwich” design creates a lightweight yet incredibly strong component that offers superior thermal insulation compared to traditional brick-and-mortar or simple metal roofing.

Why Choose PUF Panels for Your Next Project?

1. Superior Thermal Insulation

The primary reason industries switch to PUF panels is their exceptionally low thermal conductivity. By maintaining internal temperatures, these panels significantly reduce the load on HVAC systems, leading to energy savings of up to 40-50%.

2. Rapid Installation

Time is money. Since PUF panels are prefabricated, they are ready to be installed the moment they arrive at the site. This can reduce construction timelines by weeks or even months compared to traditional masonry.

3. Fire and Weather Resistance

Modern PUF panels are engineered with fire-retardant properties. Additionally, their tongue-and-groove interlocking systems ensure a leak-proof, airtight seal that protects against extreme weather conditions.

4. High Strength-to-Weight Ratio

Despite being lightweight, these panels offer high load-bearing capacities, allowing for wider spans in roofing and walling without the need for heavy internal support structures.

Technical Specifications at a Glance

When choosing a panel, it is important to understand the technical parameters that fit your specific climate and structural needs:

| Feature | Specification Range |

| Core Density | 40 kg/m³ (± 2 kg/m³) |

| Panel Thickness | 30mm to 150mm |

| Thermal Conductivity | ~0.023 W/mK |

| Temperature Range | -80°C to +80°C |

| Facing Material | PPGI, Stainless Steel, or Aluminum |

Common Applications

- Cold Storage & Food Processing: Essential for maintaining sub-zero temperatures.

- Warehouses & Industrial Sheds: Provides a durable, climate-controlled environment for inventory.

- Clean Rooms: Used in pharmaceuticals and electronics manufacturing to ensure a dust-free environment.

- Prefabricated Shelters: Ideal for quick-deploy housing or site offices.

Why Source from Astar Insulation?

At Astar Insulation, we don’t just supply materials; we provide peace of mind. Our Sandwich PUF Panels are manufactured using high-precision technology to ensure uniform density and perfect interlocking.

We prioritize sustainability and cost-effectiveness, ensuring your project meets international standards for energy efficiency and safety.

Ready to Upgrade Your Building’s Efficiency?

Don’t settle for outdated construction methods. Choose the durability and insulation power of Astar PUF Panels.

[Contact our experts today for a custom quote or technical consultation!]

- Keyword: Sandwich PUF Panel

- Keywords: Thermal insulation panels, PUF wall panels, cold storage insulation, energy-efficient construction.

- Discover why Sandwich PUF Panels are the top choice for energy-efficient construction. Learn about thermal insulation, benefits, and applications from Astar Insulation.

- “Cross-section of a high-density PUF sandwich panel for industrial insulation.”

Leave A Comment: